Construction Staff Scheduling

Effective construction staff scheduling is the cornerstone of any successful US construction project. In an industry defined by tight deadlines, complex logistics, and high labor costs, mastering construction workforce scheduling is not just an administrative task—it's a critical financial and operational strategy. This comprehensive guide covers everything from construction crew scheduling methodologies and modern scheduling software to legal compliance and risk management, providing a complete roadmap for optimizing your construction staff scheduling process.

TL;DR

Successful construction staff scheduling has evolved from static spreadsheets to dynamic, software-driven systems. The most effective firms use a hybrid methodology, combining high-level Critical Path Method (CPM) planning with field-level Last Planner System (LPS) execution. This is powered by Look-Ahead Schedules, which proactively clear constraints before they cause delays. Modern crew-based scheduling software is essential for managing resource-loaded schedules, ensuring compliance with FLSA and OSHA regulations, and providing a "single source of truth" that eliminates communication delays between the office and the field. The goal is not a rigid plan but a resilient scheduling process that can adapt to weather, staff absences, and client changes.

In This Article

- The Foundations of Construction Scheduling

- Strategic Methodologies: The Master Plan

- Tactical Planning: The Look-Ahead Schedule

- Execution Models: Crew-Based vs. Task-Based

- Resource-Loaded Scheduling: Constraints and Costs

- The Scheduler's Toolkit: Technology and Systems

- Legal and Regulatory Constraints in Scheduling

- Proactive Risk Management and Schedule Control

- The Living Schedule: Communication and Execution

- Analyst Recommendations and Strategic Conclusion

The Foundations of Construction Scheduling

A construction schedule is not merely a document or a timeline; it is the strategic, dynamic backbone of any successful project. It functions as the core management tool for planning, coordinating, and timing all necessary tasks and activities. A well-structured schedule provides clear project visibility, enforces accountability among all stakeholders, optimizes the use of finite and expensive resources, and enables proactive risk management, which is the clear differentiator between successful and failed projects.

This roadmap is defined by its ability to answer three crucial questions for every phase of the project: "What" activities and tasks need to happen, "When" they will occur (including their duration and sequence), and "Who" is required to complete the job, which encompasses the labor, equipment, and materials.

The High-Stakes Balancing Act

Effective construction scheduling is more than just filling slots. It's a complex puzzle of balancing project deadlines, budgets, labor laws, and worker skills. Getting it right means an on-time, on-budget project. Getting it wrong leads to costly overruns and delays.

Labor is one of the single largest expenses, often accounting for 40-50% of total project costs. A well-optimized schedule directly controls this massive expenditure, making it a critical lever for project profitability.

Typical Project Cost Breakdown

To manage the inherent complexity of construction, scheduling is organized into a clear hierarchy. This hierarchy flows from the high-level Master Schedule, which outlines the entire project from start to finish, to the medium-term Look-Ahead Schedule, which bridges the gap between the master plan and field operations. The look-ahead, in turn, feeds the granular Weekly and Daily Plans, which provide specific assignments to crews. This tiered system allows for long-range coordination while empowering the short-term flexibility necessary to manage a chaotic job site.

This report addresses what can be termed the "scheduling problem" in the construction industry. This problem stems from a pervasive historical shift where schedules became viewed as static "tasks" to be completed—for instance, a document to be submitted with a payment application—rather than as the dynamic project management tool they are meant to be. This fundamental conceptual failure leads to reduced visibility, poor accountability, and a culture of reactive "firefighting" rather than proactive management.

The reality of any construction project is that it will invariably face disruptions, including material delays, severe weather, staff absences, and last-minute client changes. A rigid, static schedule, no matter how accurate at its inception, will break when it contacts this reality. The common industry practice of "reactive firefighting" is a direct symptom of this static-schedule mindset. Consequently, the true value of scheduling is not found in the initial perfection of a baseline plan, but in the resilience and responsiveness of the scheduling process itself. This reframes scheduling from a simple planning function to a critical command-and-control function, where the goal is to (a) anticipate disruptions and (b) provide the real-time data needed to adapt to them intelligently.

Strategic Methodologies: The Master Plan

The choice of a scheduling methodology is a high-level strategic decision that dictates how a project is planned, measured, and controlled. This philosophy underpins every schedule created.

The 6-Step Scheduling Process

A structured process is essential for creating a schedule that is efficient, compliant, and robust. This flow outlines the critical path from initial planning to daily management.

-

1

Define Tasks & Dependencies

Break down the project plan into specific tasks and understand their sequence.

-

2

Estimate Labor Needs

Calculate the hours and crew size required for each task.

-

3

Map Skills & Compliance

Match tasks to required certifications (e.g., welder, crane operator) and labor laws.

-

4

Assign Staff & Create Schedule

Assign specific workers to tasks based on skill, availability, and cost.

-

5

Distribute & Communicate

Ensure every crew member and supervisor has the latest schedule.

-

6

Adapt to Changes

Adjust the schedule in real-time for weather, sickness, or material delays.

The Critical Path Method (CPM): The What and When

The Critical Path Method (CPM) is the industry-standard technique for planning and managing complex projects. The process is logical and sequential:

- Work Breakdown Structure (WBS): The project is first broken down into a hierarchical WBS, defining all the work into manageable packages.

- Task & Dependency Sequencing: All tasks and activities are listed and then sequenced, identifying all task dependencies (e.g., Task B cannot start until Task A is finished).

- Duration Estimating: A realistic duration is estimated for each activity.

This analysis produces the "critical path"—the longest sequence of dependent tasks that determines the minimum possible project duration. Activities on this path have zero "float," meaning any delay to a critical-path item will delay the entire project's completion date.

"Float," or "maneuvering room", represents the flexibility of non-critical tasks—the amount of time they can be delayed without affecting the project's finish date. The primary function of CPM, therefore, is to identify the critical path so that managers can deploy their most valuable resources (labor, equipment, and materials) where they will have the greatest impact.

The Last Planner System (LPS): The Who and How-Ready

The Last Planner System (LPS) is a fundamentally different, collaborative, and commitment-based planning system rooted in the principles of Lean Construction.

Unlike CPM, which often "pushes" a schedule onto the field, LPS operates on a "pull" system. It puts decision-making and commitment authority into the hands of the "last planners"—the foremen and crew leads who are responsible for executing the work.

LPS is executed through a series of collaborative meetings that integrate constraint analysis, lookahead scheduling, and weekly work planning. The core principle is that work is only "pulled" from the backlog and scheduled for execution after it is vetted for readiness and the workforce has the capacity to perform it. This collaborative approach fosters far greater buy-in, improves team communication, and proactively manages risk by identifying constraints (e.g., "We can't do that task next week because the materials won't be here") long before they become delays.

Comparative Methodologies: PERT and LOB

Two other methodologies are often used for specific project types:

- Program Evaluation and Review Technique (PERT): PERT is a statistical tool used to manage high uncertainty in task durations. Instead of CPM's single duration estimate, PERT uses three-point estimates (optimistic, pessimistic, and most-likely) to calculate a probabilistic project duration. It is ideal for R&D-heavy or highly unpredictable projects.

- Line of Balance (LOB): LOB is the preferred methodology for repetitive-task projects, such as high-rise apartment buildings, road sections, or pipelines. LOB focuses on productivity rates and the physical flow of crews through different locations or zones. Its goal is to optimize the workflow to prevent trade-stacking and ensure crews can move seamlessly from one unit to the next.

These methodologies are often presented as competing, but this represents a false choice. A mature construction firm operates a hybrid system. CPM is excellent for high-level, long-range planning and defining the contractual milestones. However, a master schedule's weakness is that it's disconnected from field-level reality and cannot be accurately detailed far into the future. LPS, conversely, is unparalleled at short-term, field-level execution, collaboration, and constraint removal, but it requires a high-level schedule to "pull" from.

These systems are not competitive; they are symbiotic. Lookahead planning, a key component of LPS, explicitly stands between the overall project schedule (CPM) and crew-level commitments. A mature firm uses its CPM Master Schedule to define the destination (e.g., "Complete Foundation by March 30"). It then uses the LPS process to navigate the journey, ensuring all constraints are cleared so crews can reliably hit that CPM milestone.

| Methodology | Core Principle | Primary Unit of Analysis | Best For | Handles Uncertainty |

|---|---|---|---|---|

| Critical Path Method (CPM) | Task-based dependency logic | Tasks & Activities | Complex, unique projects (e.g., hospitals, data centers) | Poorly (Relies on managing "float") |

| Last Planner System (LPS) | Commitment-based "pull" planning | Crew Commitments & Constraints | Collaborative field execution; complex, fast-track projects | Excellently (Proactively identifies and removes constraints) |

| Line of Balance (LOB) | Repetitive-flow optimization | Production Rate per Zone/Unit | Repetitive, linear projects (e.g., high-rises, roads) | Poorly (Assumes stable, repeatable production rates) |

| Program Evaluation & Review (PERT) | Probabilistic time management | Task Duration Uncertainty | R&D-heavy or highly unpredictable projects | Excellently (Statistically quantifies uncertainty) |

Tactical Planning: The Look-Ahead Schedule

While CPM and LPS provide the strategy, the Look-Ahead schedule is the tactical engine that drives daily operations. It is arguably the most critical scheduling function, yet it is often "poorly performed" in the industry. Its purpose is to convert the static master plan into an actionable, "make-ready" inventory of work for the field.

The Look-Ahead as a Constraint Filter

The main objective of the Look-Ahead schedule is not simply to inform crews of future tasks. Its primary, critical function is to screen tasks from the master schedule against their readiness. It is a system designed to "identify roadblocks and constraints".

This process is typically managed on a six-week horizon. For every single activity planned within the next six weeks, the superintendent and project team must ask a checklist of questions: "Do I have the labor, materials, equipment, permissions, and layout I need?".

If the answer is "no," that activity is marked as a constraint or "roadblock" and is not released to the field. This process creates two distinct and vital lists:

- A backlog of tasks that are 100% ready to be assigned.

- A list of constraints that must be resolved by management (e.g., "Call supplier," "Get RFI answered").

This screening process is what "improves the success rate of completing the tasks assigned" by ensuring that a crew never mobilizes to a work area only to find they are missing a part, a permit, or a piece of equipment.

Integrating the Look-Ahead into Field Operations

The Look-Ahead operates on a cascading timeline:

- 6-Week Look-Ahead: This horizon is ideal for identifying and resolving long-lead-time constraints, such as materials, procurement, or complex RFI resolutions.

- 3-Week Look-Ahead: This is the window for detailed trade coordination and aligning crew sizes.

- Weekly Work Plan (WWP): This is the final, granular plan for the coming week, developed from the "make-ready" tasks vetted by the look-ahead process. This plan represents a firm commitment from the crews.

- Daily Huddle: A quick 15-minute meeting where teams review the daily plan and discuss the next day's work.

Critically, this planning process cannot be "forced upon" the trades. It must be a collaborative effort. The most effective implementation is through weekly foreman meetings, where superintendents and trade partners review the look-ahead together and commit to the upcoming plan. This collaborative buy-in is the "cornerstone" of the Last Planner System.

This look-ahead process is, in effect, the project's financial immune system. Its effectiveness is the single greatest predictor of labor productivity and a leading indicator of project profit margin. Ineffective planning—often signified by a short, 1-week look-ahead—is constantly reactive. It leads to mis-sized crews (who show up with too many or too few workers), "idle time" (as crews wait for work), and production "bottlenecks". These are all direct, severe drains on the project's labor budget.

Conversely, a project with a high-performing 6-week look-ahead identifies a material roadblock weeks in advance. This allows the project manager to resolve the constraint or, if necessary, reschedule the crew before they are mobilized, saving thousands in wasted labor costs. The Look-Ahead is not an administrative task; it is the primary tool for protecting the project's profit.

Execution Models: Crew-Based vs. Task-Based Deployment

Once a plan is established, work must be assigned. The choice of how to organize and assign that work falls into two primary models, which have significant implications for resource management.

Task-Based Scheduling (The WBS Approach)

This is the traditional model, derived directly from a CPM-style Work Breakdown Structure (WBS). The focus is entirely project-centric. The project manager breaks the overall project into smaller tasks, and then allocates the necessary resources—labor, materials, and equipment—to each individual task. The "task" or "deliverable" is the central organizing principle.

Crew-Based Scheduling (The Operational Approach)

This model organizes the schedule around the crew as the primary unit of analysis. The goal is to create a "synchronized system where the right workers with the right skills arrive at the right locations precisely when needed".

This approach is company-centric and resource-centric, focusing on the efficient use of the company's entire labor pool. It involves:

- Task-Based Assignment: Organizing crews based on their specialized skill (e.g., foundation crew, framing crew, electrical crew).

- Project Phase Allocation: Deploying these specialized crews sequentially to different projects as they enter the relevant phase.

- Multi-Project Coordination: Actively managing and scheduling crew assignments across multiple job sites simultaneously to maximize labor utilization and minimize downtime.

Modern construction software is built to support this model, allowing operations managers to see crew availability, prevent scheduling conflicts, and assign a "crew lead" for a single point of accountability.

A construction firm's operational maturity can be measured by its ability to integrate task-based project schedules with crew-based resource schedules. The failure to do this is a primary driver of resource conflicts and project delays. A project manager, using a task-based schedule, identifies that "Task 5.1: Install Framing" needs to start on Monday. An operations director, looking at the company's resources, knows that the "Framing Crew" is the only one with the right skills. The conflict arises when the operations director sees that the Framing Crew is already scheduled on a different project that day.

A firm using only simple, task-based schedules has no mechanism to see this cross-project resource conflict until it is too late. A firm using a crew-based system identifies this conflict during the look-ahead phase and can resolve it. Therefore, crew-based scheduling is the necessary operational layer that allows a firm to successfully execute its portfolio of task-based project schedules.

Resource-Loaded Scheduling: Integrating Constraints and Costs

A schedule that only includes tasks and timelines is a "wish list," not a plan. A professional schedule must be "loaded" with the real-world constraints of labor, skills, materials, equipment, and cost.

Core Scheduling Variables

A project manager must juggle numerous competing factors. The relative importance and complexity of these key variables show the core challenge of scheduling: balancing all these "pulls" at once.

Skill-Based Deployment and Compliance

A staff deployment plan is essential for aligning the right types of crews with the correct project phases. It is insufficient to simply schedule "an operator." The schedule must deploy an operator certified for the specific piece of equipment being used. This is a non-negotiable legal and safety mandate.

Furthermore, the schedule must function as a compliance tool. It must track and verify that every worker assigned to a task has the required safety training (e.g., OSHA certification). Modern workforce management software is essential for this, providing a centralized, cloud-based database of all worker skills, licenses, and certifications. This software sends automated alerts for expirations and allows a scheduler to filter the workforce by "required skill", ensuring a compliant and qualified worker is assigned to every task.

Coordinating Materials and Equipment

The most common scheduling failure is an "unrealistic resource projection". Work grinds to a halt if crews are available but the materials or equipment are not. Therefore, the staff schedule must be integrated with the procurement and material delivery schedule. This requires factoring in lead times, maintaining constant communication with suppliers, and using the look-ahead process to confirm material availability before mobilizing the crew.

Integrating Labor Costs: The Union vs. Open Shop Analysis

The choice of a union or open-shop (non-union) labor model is a critical strategic decision that has profound impacts on scheduling, cost, and predictability.

- The Union Position: Proponents argue that while hourly wages may be higher, the total project cost is reduced by an average of 4% when using union labor. This is attributed to several factors: predictable labor costs, 14% higher productivity, and a significantly higher skill level from robust apprenticeship programs. Most importantly, union projects benefit from one-third less labor turnover. Since high turnover and a shortage of skilled labor are directly linked to cost overruns and schedule slips, the union model is presented as a strategy for mitigating schedule risk by ensuring schedule predictability.

- The Open-Shop/Non-Union Position: This perspective argues that government-mandated Project Labor Agreements (PLAs), which require adherence to union rules, substantially increase taxpayer costs. The argument is that PLAs create an uncompetitive environment that effectively precludes nonunion bids. These mandates create operational burdens by forcing contractors to hire from unfamiliar union hiring halls rather than their own trusted teams, adhere to inefficient union work rules that limit the diversity of tasks a worker can perform, and duplicate benefit payments by paying into union funds while also maintaining their own company plans. The open-shop model argues it provides greater flexibility and productivity advantages, which are undermined by "burdensome" PLA mandates.

This debate is fundamentally an argument about who is better at managing schedule risk. It is a strategic choice between mitigating market risk (the union model's solution to labor shortages and turnover) and operational risk (the open-shop model's focus on workforce flexibility).

The NABTU study makes a direct causal link: higher craft skills lead to better schedule predictability and lower total cost. Their argument is that unions are the best way to mitigate the market risk of skilled labor shortages, which are a primary cause of schedule slips.

The ABC argument focuses on operational risk. They contend that PLA mandates create schedule risk by preventing contractors from using their own known, productive teams and forcing them to use an "unfamiliar workforce" bound by "standardized union work rules" that undermine "productivity advantages".

A scheduler must understand this is not a simple cost-benefit analysis. Choosing a union model is a strategy to outsource the risk of skill acquisition and workforce stability. Choosing an open-shop model is a strategy to insource that risk in exchange for greater operational flexibility and control (assuming a mandated PLA is not in place).

| Metric | Pro-Union Position | Open-Shop / Anti-PLA Position |

|---|---|---|

| Total Project Cost | 4% lower | Substantially higher (e.g., 21% on LA housing) |

| Productivity | 14% higher | Hindered by "standardized union work rules" |

| Schedule Predictability | Better, due to higher craft skills | Worse, due to "unfamiliar workforce" from hiring halls |

| Skill Level | Significantly higher | Variable; not discussed as an inherent advantage |

| Workforce Stability | One-third less turnover | Higher turnover is a risk of the open-shop market |

| Operational Flexibility | Limited by work rules | Primary advantage (undermined by PLAs) |

The Scheduler's Toolkit: Technology and Systems

The tools used to create, manage, and communicate the schedule are as important as the methodology itself. The choice between manual spreadsheets and modern, dedicated software is a critical decision.

The Spreadsheet Dilemma: The Wrong Tool for the Job

Using spreadsheets (like Excel) for complex construction scheduling is "like trying to drive a screw with a hammer". While they are cheap, flexible, and have a low barrier to entry, they are fundamentally unsuited for the job and have "deal-breaking" flaws:

- They Are Not Collaborative: Spreadsheets are "not a collaborative scheduling technique". This leads to "version control confusion", where multiple, conflicting, and outdated versions of the schedule are sent via email.

- They Are Not Real-Time: Every update is a "laborious process" that must be done manually. They do not update in real-time.

- They Are Not Mobile: They do not support field mobility well.

- They Are Error-Prone: The reliance on manual data entry significantly "increases the risk of human error," where one missed update can "throw your entire project off track".

- They Reduce Accountability: It is difficult to track changes or know who is working off which version, which reduces accountability.

Modern Scheduling and Workforce Management Software

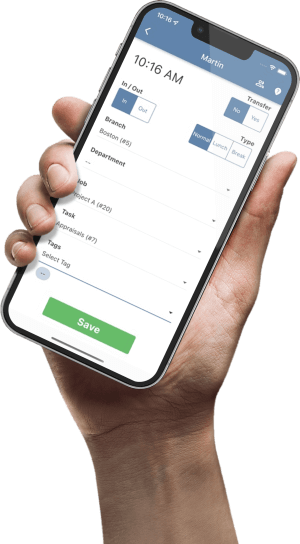

Dedicated construction scheduling software solves the spreadsheet's core problems by creating a single source of truth for the entire project team. These platforms are cloud-based, inherently collaborative, and, most importantly, provide robust mobile access for the field.

Critical features of modern software include:

- Office-to-Field Sync: Real-time updates from the field (e.g., a foreman marking a task complete on a tablet) instantly flow to the office, and schedule changes from the PM are instantly pushed to the field.

- Crew & Resource Management: Tools to manage crew allocation, track availability in real-time, and prevent resource conflicts.

- Task Management & Visualization: Dynamic Gantt charts, calendar views, and clear task assignment lists.

- Time Tracking & Compliance: Digital time cards often integrated with geofencing to verify crew location and prevent time-theft.

- Integration: The ability to connect with other essential systems, such as Procore, Primavera, or company ERPs.

Market Landscape Overview

The software market can be broadly categorized:

- All-in-One Platforms: (e.g., Procore, Buildertrend) offer comprehensive project management suites that include scheduling, financials, and field management.

- Field-Focused Tools: (e.g., Fieldwire) excel at document management, task management, and subcontractor coordination on-site.

- Workforce Management Tools: (e.g., TimeTrex, Connecteam, Workyard) specialize in employee-level scheduling, time tracking, and communication.

- Specialized Scheduling Tools: (e.g., Asta Powerproject, Planera, Outbuild) are designed for professional schedulers and advanced look-ahead planning, often with strong CPM and lean capabilities.

The strategic adoption of scheduling software is not an IT expense but an investment in operational velocity. The return on this investment is measured in the compression of the communication-delay-loop. With spreadsheets, the time lag between a field event (a delay) and a re-plan is 24-48 hours: the foreman writes it on paper, drives to the office, the PM manually updates the file, and then emails the new, (already outdated) version to the other trades.

Modern mobile, cloud-based software eliminates this loop. A foreman marks a task "complete" on a tablet. The PM instantly sees the update in the office. The next subcontractor instantly gets a push notification that their predecessor task is done and they can mobilize. This compresses the 2-day communication delay into seconds. This operational velocity—the speed at which a project can react to reality—is the single greatest advantage of dedicated software and a direct driver of productivity.

| Capability | Spreadsheets (e.g., Excel) | Dedicated Software (e.g., TimeTrex, Procore) |

|---|---|---|

| Real-Time Updates | Manual; "Version control confusion" | Automatic; "Single source of truth" |

| Field Mobility | Poor; Not designed for mobile devices | Excellent; Mobile-first apps are standard |

| Collaboration | Poor; "Not a collaborative technique" | Excellent; Cloud-based, multi-user access |

| Constraint Tracking | Manual; Not integrated or visible | Integrated; "Mark roadblocks" in real-time |

| Crew/Skill Allocation | Manual; Prone to resource conflicts | Automated; "Optimize resources" and manage availability |

| Accountability | Low; "Reduce accountability" | High; Digital log of all changes and updates |

Legal and Regulatory Constraints in Scheduling

A construction schedule is not just a plan; it is a legal document. It dictates pay, ensures worker safety, and creates an auditable record of compliance or non-compliance. Failure in this area exposes a firm to significant liability.

Federal Labor Laws: FLSA

The Fair Labor Standards Act (FLSA) dictates the core rules for pay:

- Overtime: Non-exempt employees must be paid at 1.5 times their regular rate of pay for all hours worked over 40 in a single workweek. It is critical to understand that each workweek stands alone. The common practice of "banking" overtime hours or offering "comp time" in lieu of pay is illegal for private-sector employers.

- Breaks and Meal Periods: Federal law does not require employers to provide breaks. However, if breaks are offered, the rules are strict:

- Short rest breaks (5-20 minutes) are considered part of the workday and must be paid.

- Bona-fide meal periods (typically 30 minutes or more) are not compensable, but only if the employee is "completely relieved of all duties". If a foreman eats lunch at their desk while answering the phone or reviewing plans, that is a "working lunch" and must be paid.

State & Local Compliance (Case Study: Texas)

Schedulers must manage a complex patchwork of regulations that change between states, counties, and even cities.

- Overtime (Texas): Texas law generally aligns with the FLSA 40-hour workweek. In any conflict, the stricter law (usually federal) controls.

- Breaks (Texas): Like federal law, the state of Texas does not mandate rest breaks. However, some cities do. The city of Austin, for example, passed an ordinance requiring construction employers to provide a 10-minute paid rest break for every four hours worked. This demonstrates that a scheduler must know the law down to the municipal level.

- Sick Leave (Texas): There is no state-level law requiring paid sick leave. However, this does not mean it's a non-issue. A contractor working on a federal project is subject to Executive Order 13706, which mandates paid sick leave. This shows how two identical projects in the same city can have different scheduling and pay requirements based on the client.

OSHA and Worker Fatigue

Scheduling is a primary safety function. Worker fatigue is a major hazard linked to industrial disasters.

- The Risks: Long work hours (over 40 per week) and extended shifts (12+ hours) lead to increased stress, poor health, and a significantly higher risk of injury. Research indicates that working 12-hour days is associated with a 37% increased risk of injury.

- OSHA Guidelines: OSHA guidelines state that employers have a responsibility to manage fatigue. This includes arranging schedules to allow for adequate rest breaks and nighttime sleep, examining workloads and understaffing, and implementing a formal "Fatigue Risk Management Plan".

The daily staff schedule serves as a primary legal and financial compliance artifact. Every scheduling decision creates a quantifiable, auditable record. When a scheduler puts "Crew A: 7 am - 7 pm," that entry is now evidence of a 12-hour shift. In the event of an accident, that schedule, combined with OSHA data, could be used to demonstrate that the company knowingly created a 37% higher risk of injury. A time card showing a 25-minute "meal break" is evidence for a wage-theft claim. This reinforces the need for modern scheduling software like TimeTrex that can have compliance rules and alerts built directly into the system.

Proactive Risk Management and Schedule Control

As President Dwight D. Eisenhower stated, "In preparing for battle I have found that plans are useless, but planning is indispensable". Construction scheduling is not about creating a perfect plan, but about building a resilient planning system that can anticipate and manage the inevitable disruptions that derail projects.

Common Schedule Disruptors

No schedule survives contact with reality. The best schedulers anticipate and plan for common disruptions. These are the most frequent causes of schedule variance on construction sites, matching directly with the risks that must be managed.

Managing Weather Delays

The Wrong Way: Simply adding a generic "10-day rain buffer" to the end of the project schedule. This is reactive and fails to account for how weather impacts specific work. It is a common way to lose delay-day claims.

The Right Way: A proactive, data-driven approach is required.

- Identify Vulnerabilities: Determine which critical path activities are sensitive to specific weather (e.g., concrete pours, roofing, steel erection in high wind).

- Use Data: Use historical weather data to create a "weather calendar" that builds in a realistic number of non-work days by season (e.g., more non-work days in February than in July).

- Build Flexibility: The most effective strategy is to plan alternative tasks. When a critical-path outdoor task is halted by rain, the crew is immediately re-sequenced to a planned interior task, allowing them to remain productive.

- Contractual Clarity: The contract must clearly define what constitutes an excusable weather delay, and any claim must be tied to a documented impact on a critical path activity.

Managing Staff Absences and No-Shows

Employee absenteeism is a "growing problem" in construction. It directly delays projects by creating bottlenecks, and it increases stress and lowers morale for the remaining crew members who must cover the work.

Managing this risk requires a four-part system:

- Policy: Establish clear attendance policies, procedures for requesting time off, and a "progressive disciplinary process" for no-shows.

- Culture: Foster a supportive work environment that addresses mental health (a key driver of absenteeism) and offers incentives for good attendance.

- Planning: The most powerful tool is cross-training employees. This creates a flexible and resilient workforce where one person's absence does not shut down an entire operation. Build backup plans, including relationships with temporary staffing agencies.

- Technology: Use scheduling software to get real-time alerts on no-shows and to manage shift-swapping, which allows employees to cover for each other easily.

Managing Last-Minute Changes and Change Orders

Changes will occur on every project. Unrealistic schedules that do not account for this are a common pitfall. A resilient schedule is managed with a formal, transparent process:

- Embrace Flexibility: A flexible mindset is essential; dwelling on the disruption is counterproductive.

- Document Formally: All changes, no matter how small, must be documented in a formal Change Order that details the impact on scope, cost, and timeline.

- Evaluate Impact Immediately: As soon as a change is proposed, the scheduler's first job is to evaluate its impact on material lead times, cost, and the critical path.

- Communicate Transparently: Immediately and honestly communicate these impacts to the client and all affected subcontractors.

- Adjust the Schedule: Once the change is approved, formally adjust the schedule by reallocating resources, considering phased work, or (with client approval) adjusting the final timeline.

A resilient schedule is one that is not brittle but flexible. The primary goal of risk management in scheduling is to proactively build in this flexibility. Flexible sequencing counters weather. A flexible, cross-trained crew counters absences. A flexible, transparent process counters client changes. A rigid plan, staffed by rigidly-specialized crews, and managed with a rigid change process is guaranteed to fail.

| Risk Event | Proactive Mitigation (Planning Phase) | Reactive Mitigation (Execution Phase) |

|---|---|---|

| Weather Delay | Build seasonal weather calendar from historical data. Identify and prioritize vulnerable critical path items. | Resequence crews to pre-planned, non-exposed interior work. Document impact on critical path for excusable delay claim. |

| Staff No-Show | Cross-train crews to create a flexible workforce. Establish clear, progressive attendance policy. | Use real-time alerts to notify supervisor immediately. Call in pre-vetted backup from staffing agency or "float" pool. |

| Material Delay | Integrate supplier lead times into master schedule. Diversify suppliers to reduce single-point failure. | Reallocate crew to a non-dependent task (if possible). Evaluate "crashing" other activities to make up time. |

| Client Change Order | Build a schedule buffer (contingency time). Establish a formal change order process in the contract. | Immediately document the change and evaluate its impact on the critical path. Communicate cost and time impacts to owner before proceeding. |

The Living Schedule: Communication, Visualization, and Execution

The best plan is useless if it remains in a three-ring binder in the site trailer. A schedule must be a "living" tool that is clearly visualized, effectively communicated, and universally adopted by the team in the field.

Visualization: The Gantt Chart and the Critical Path

Gantt charts are the primary tool for visualizing the project timeline. They provide a clear, at-a-glance bar chart view of tasks, durations, and dependencies, acting as a single source of truth for all stakeholders, including subcontractors, engineers, and clients.

A modern Gantt chart is not just a task list; it is a resource scheduler. Effective charts visually assign team members and resources (like cranes or excavators) to each task bar. This allows a project manager to see the workload per employee or per crew and directly connects the critical path to specific crew deployments.

Communication Protocols: From Office to Field

Poor communication is a primary driver of project failure. It leads to costly errors, safety issues, and cascading delays.

Best Practices:

- Clarity and Brevity: Communication must be simple, brief, and focused on the immediate tasks.

- Rhythm: A firm rhythm of communication is essential: daily huddles to plan the day, weekly foreman meetings to commit to the look-ahead, and regular check-ins with stakeholders.

- Use Technology: A modern site cannot rely solely on paper, email, or whiteboards. It must use modern construction management software to push instant updates and schedule changes directly to the crews' mobile devices.

- Subcontractor Communication: This is often the weakest link. Using dedicated platforms (e.g., Procore, Fieldwire, eSUB) is critical for managing subcontractor schedules and creating a centralized, auditable log for all communication, especially for change orders.

Analog vs. Digital Field Communication

The tools used for in-the-moment communication on-site are critical.

- Analog (Two-Way Radios): These devices are simple, familiar, and have a low upfront cost. However, they suffer from significant limitations in a noisy construction environment: static, interference, and poor audio. Their biggest drawback is that they are limited to one conversation per channel.

- Digital (Radios & Mobile Apps): Digital radios and mobile apps provide crystal-clear audio with built-in background noise reduction. They also offer advanced data features like text messaging, GPS location, and status updates. The main trade-off is the "digital cliff": audio is perfect until it goes out of range, at which point it drops completely, unlike analog's gradual fade.

The transition from analog to digital communication is not about audio clarity; it is a fundamental shift from voice-centric to data-centric communication. This shift is what enables a truly living schedule.

Analog communication is ephemeral. A foreman radios to a PM, "We're done with the pour." This is a one-to-one, non-logged, verbal-only event. Digital communication, via a mobile app or an advanced digital radio, is data. The foreman marks a task "Complete" on a tablet. This single data point triggers an automated workflow: the master Gantt chart updates, the PM is notified, the next subcontractor in the chain is automatically alerted, and a permanent, auditable log of the event is created for accountability. Digital communication is the schedule, transforming it from a static picture on a wall into a real-time dashboard updated live from the field.

How Do You Measure Success?

An effective schedule isn't just a feeling; it's a measurable outcome. Key Performance Indicators (KPIs) track schedule effectiveness by comparing planned metrics to actual results. This variance highlights areas for improvement and is a core function of a "living" schedule.

Analyst Recommendations and Strategic Conclusion

This report has provided an exhaustive analysis of the interconnected systems required for expert-level construction staff scheduling. We have demonstrated that scheduling is a dynamic, high-stakes function that serves as the strategic backbone of project management, legal compliance, and financial control. The following recommendations provide a strategic roadmap for a construction firm to evolve its scheduling capabilities from reactive to proactive.

- Recommendation 1: Adopt a Hybrid, Integrated Methodology. The debate between CPM and LPS is a false choice. A mature firm must use both. Use CPM to establish the high-level, long-range Master Schedule required for contractual and milestone planning. Implement the Last Planner System (LPS) as the field-level execution engine, using collaborative 6-Week Look-Ahead Planning and Weekly Work Plans to ensure trade buy-in and proactive constraint removal.

- Recommendation 2: Mandate a "Single Source of Truth" Technology Stack. Firms must immediately abandon spreadsheets as a primary scheduling tool. The ROI of a modern, cloud-based, mobile-first platform is not an "IT expense" but a direct investment in operational velocity. The goal is to eliminate communication float by creating a single, real-time data environment that connects the field superintendent's tablet to the project manager's dashboard.

- Recommendation 3: Transition from Task-Based to Resource-Driven Scheduling. Evolve planning from simple task-based lists to a resource-loaded, crew-based model. The scheduling system must integrate a robust database of worker skills, mandatory certifications, and safety training. This is the only way to ensure that a qualified and compliant crew is deployed to the right job, at the right time, across a multi-project portfolio.

- Recommendation 4: Embed Compliance and Risk into the Schedule. The schedule must be treated as a primary compliance and risk management artifact. The scheduling system and its managers must be programmed to adhere to all FLSA overtime and break rules, all state and local labor laws (such as city-specific break ordinances), and OSHA's fatigue management guidelines.

- Recommendation 5: Build a Resilient System Based on Flexibility.

The ultimate goal of scheduling is not to create a rigid plan that breaks, but a resilient system that adapts. This resilience is achieved through flexibility:

- Flexible Crews: Implement cross-training programs to mitigate the impact of staff absences.

- Flexible Sequencing: Actively plan for weather-contingent interior work to protect the critical path.

- Flexible Processes: Enforce a transparent, formal change order process to manage scope changes without causing project chaos.

Final Conclusion: The difference between a high-performing and a low-performing construction firm is the difference between proactive scheduling and reactive firefighting. A robust, integrated, and well-communicated staff schedule is the ultimate tool for controlling costs, mitigating risk, and delivering projects with the one thing all clients demand: predictability.

Master Your Construction Staff Scheduling

Stop fighting fires and start planning proactively. TimeTrex provides an all-in-one workforce management solution built for the construction industry. Manage crew schedules, track time and attendance with geofencing, ensure FLSA and OSHA compliance, and connect your entire team from the office to the field—all on a single platform.

Disclaimer: The content provided on this webpage is for informational purposes only and is not intended to be a substitute for professional advice. While we strive to ensure the accuracy and timeliness of the information presented here, the details may change over time or vary in different jurisdictions. Therefore, we do not guarantee the completeness, reliability, or absolute accuracy of this information. The information on this page should not be used as a basis for making legal, financial, or any other key decisions. We strongly advise consulting with a qualified professional or expert in the relevant field for specific advice, guidance, or services. By using this webpage, you acknowledge that the information is offered “as is” and that we are not liable for any errors, omissions, or inaccuracies in the content, nor for any actions taken based on the information provided. We shall not be held liable for any direct, indirect, incidental, consequential, or punitive damages arising out of your access to, use of, or reliance on any content on this page.

About The Author

Roger Wood

With a Baccalaureate of Science and advanced studies in business, Roger has successfully managed businesses across five continents. His extensive global experience and strategic insights contribute significantly to the success of TimeTrex. His expertise and dedication ensure we deliver top-notch solutions to our clients around the world.

Time To Clock-In

Start your 30-day free trial!

Experience the Ultimate Workforce Solution and Revolutionize Your Business Today

- Eliminate Errors

- Simple & Easy To Use

- Real-time Reporting

Saving businesses time and money through better workforce management since 2003.

Copyright © 2025 TimeTrex. All Rights Reserved.