Free Manufacturing Employee Schedule Generator

Manufacturing Employee Schedule Generator

Onboard Employee

Active Workforce Roster

No employees registered.

Facility Parameters

Line Staffing Requirements

| Shift Name | Start | End | Headcount |

|---|

Production Schedule

| Shift |

|---|

Bench / Off-Shift Pool

Estimated Labor Cost

Total Production Man-Hours

Payroll Breakdown by Department

| Employee | Job Title | Total Hrs | Rate | Dept Cost |

|---|

Found our Free Manufacturing Employee Schedule Generator useful? Bookmark and share it.

Quick Navigation:

TL:DR

This guide outlines the effective use of the Manufacturing Employee Schedule Generator. The tool is designed to streamline factory shift planning by integrating role-based requirements, labor budgets, and shift patterns. Users can onboard staff with specific certifications, configure facility parameters such as shift cycles and budgets, and utilize auto-scheduling algorithms to fill production lines instantly. The system also provides real-time cost variance analysis and exportable reports for payroll.

Managing Your Workforce Roster

The foundation of an efficient production schedule is an accurate workforce roster. The "Workforce Roster" tab serves as the central database for all employee information. Before generating a schedule, you must populate the system with your available labor pool.

Onboarding Employees

You can add employees individually using the form provided. This ensures that the auto-scheduler understands the specific constraints and skills of each worker. Required fields include the employee's full name, role, hourly rate, and weekly hour limits.

The generator supports various roles categorized by department. Assigning the correct role is critical for the logic engine to ensure safety compliance (e.g., ensuring a Safety Officer is present on every shift).

| Department | Key Roles | Primary Function |

|---|---|---|

| Management & Supervision | Plant Manager, Shift Supervisor, Line Lead | Oversight and team leadership |

| Production & Assembly | CNC Operator, Assembly Tech, Machine Tender | Core manufacturing and fabrication |

| Quality & Safety | QA Inspector, Safety Officer | Compliance and product verification |

| Logistics & Maintenance | Maintenance Tech, Forklift Driver, Warehouse Clerk | Equipment uptime and material handling |

Using Demo Data

For training purposes or to test different shift strategies without manual entry, use the "Load Demo Factory Crew" button. This populates the roster with a realistic mix of certified staff, including CNC operators and safety officers, allowing you to simulate a full production floor immediately.

Configuring Production Lines and Shifts

The "Line Config" tab allows production managers to define the operational parameters of the facility. This is where you align the schedule with your labor budget and production targets.

Facility Parameters

To ensure accurate payroll tracking, the "Shift Cycle Start Date" must be set to a Monday. The system validates this automatically to align with standard industrial payroll weeks. You must also define a "Target Weekly Labor Budget" to track financial variance in real time.

Shift Strategy Selection

Different manufacturing environments require different coverage models. The generator includes presets for common industrial shift patterns. Changing the strategy automates the setup of start times and headcount requirements.

| Strategy | Structure | Ideal Application |

|---|---|---|

| Standard 3-Shift | Three 8-hour shifts (Day, Swing, Night) | 24-hour continuous production operations |

| Continental / 12h | Two 12-hour shifts (Day Crew, Night Crew) | Maximizing weekend coverage and reducing turnover |

| Compressed Week | Four 10-hour shifts (4x10) | Facilities offering three-day weekends to staff |

Customizing Requirements

Beyond the presets, you can manually add "Overtime Blocks" or split shifts using the "Add Overtime/Split Shift" button. This is useful for temporary surges in demand where an overlapping mini-shift is required during peak hours.

Building the Production Board

The "Production Board" tab is the visual workspace where the schedule is finalized. This interface offers both automated logic and manual control.

Auto-Schedule Logic

Clicking the "Auto-Schedule" button triggers an algorithm designed specifically for manufacturing. It prioritizes filling "Core" roles first (Supervisors and Safety Officers) before assigning skilled labor (CNC Operators) and general labor. The algorithm respects employee blackout dates and maximum hour caps unless the "Allow Heavy OT" override is enabled.

Manual Adjustments

Production needs are dynamic. You can drag and drop employees from the "Bench / Off-Shift Pool" directly into specific shift slots.

- Drag: Move an employee card from one day to another to balance the line.

- Remove: Hover over an assigned card and click the "X" to return the worker to the pool.

- Filter: Use the department filters (e.g., "Production Only") to view specific teams without visual clutter.

Cost Analysis and Exporting

Effective labor management requires constant financial monitoring. The stats panel updates dynamically as you move employees, providing immediate feedback on the financial impact of your scheduling decisions.

Variance Tracking

The "Estimated Labor Cost" indicator compares the scheduled hours against your defined budget. It displays a clear variance figure, showing whether you are "Over Budget" (Red) or "Under Budget" (Green). This helps Plant Managers make informed decisions about approving overtime.

Payroll Breakdown

A detailed table breaks down costs by department, showing total hours and cost per employee. This granular view helps identify which departments are driving labor overages.

Export Options

Once the schedule is finalized, use the export tools to distribute it:

| Export Type | Function |

|---|---|

| Capture Board | Downloads a PNG image of the visual schedule to print for the breakroom. |

| Export Payroll .XLSX | Generates an Excel file with tabs for the schedule and payroll calculations. |

Streamline Your Manufacturing Operations

Manual spreadsheets are prone to error and difficult to scale. For a comprehensive solution that handles complex certifications, compliance rules, and automated attendance tracking, professional software is essential.

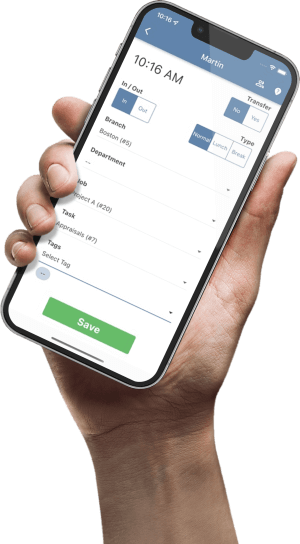

Upgrade your facility management with TimeTrex Manufacturing Scheduling Solutions.

Explore Manufacturing SolutionsDisclaimer: The content provided on this webpage is for informational purposes only and is not intended to be a substitute for professional advice. While we strive to ensure the accuracy and timeliness of the information presented here, the details may change over time or vary in different jurisdictions. Therefore, we do not guarantee the completeness, reliability, or absolute accuracy of this information. The information on this page should not be used as a basis for making legal, financial, or any other key decisions. We strongly advise consulting with a qualified professional or expert in the relevant field for specific advice, guidance, or services. By using this webpage, you acknowledge that the information is offered “as is” and that we are not liable for any errors, omissions, or inaccuracies in the content, nor for any actions taken based on the information provided. We shall not be held liable for any direct, indirect, incidental, consequential, or punitive damages arising out of your access to, use of, or reliance on any content on this page.

Trusted By

Trusted by 3.2M+ Employees: 21 Years of Service Across Startups to Fortune 500 Enterprises

Join our ever-growing community of satisfied customers today and experience the unparalleled benefits of TimeTrex.

Strength In Numbers

Join The Companies Already Benefiting From TimeTrex

Time To Clock-In

Start your 30-day free trial!

Experience the Ultimate Workforce Solution and Revolutionize Your Business Today

- Eliminate Errors

- Simple & Easy To Use

- Real-time Reporting

Saving businesses time and money through better workforce management since 2003.

Copyright © 2025 TimeTrex. All Rights Reserved.