Time and Attendance in the Manufacturing Industry: 2026

Article Index

TL;DR

The manufacturing sector is undergoing a digital revolution known as Industry 4.0. Beyond robotics, this shift requires evolving "Time and Attendance" from administrative payroll tasks to strategic engines for efficiency and risk mitigation. This guide explores the unique challenges of 24/7 facility management, the "2-2-3" schedule, and data sovereignty. We analyze how TimeTrex Workforce Management Systems addresses these needs through on-premise deployment, biometric facial recognition, and granular job costing, comparing it against competitors like ADP and Kronos (UKG).

The Operational Landscape of Modern Manufacturing

To understand the efficacy of any software solution, one must first deeply understand the problem space it inhabits. Manufacturing environments present a unique set of constraints: downtime costs thousands of dollars per minute, and safety violations can lead to catastrophic injury or facility closure.

The Challenge of Continuous Operations and Payroll Leakage

Unlike office environments, manufacturing facilities often run 24/7 to maximize capital return. This necessitates complex shift patterns, like the 2-2-3 schedule, which pushes the limits of manual tracking. Before adopting automated solutions, plants often bleed money through "payroll leakage"—a combination of human error, unauthorized overtime, and time theft.

Sources of Payroll Leakage

Breakdown of lost revenue due to inefficient tracking methods.

Shift & Overtime Complexity

Comparison of regular vs. overtime costs across departments highlighting manual scheduling pitfalls.

Managing these complex schedules manually invites disaster. The primary mistakes include under-staffing, scheduling unqualified employees for specific machinery, or triggering unauthorized overtime. Furthermore, manual systems lead to operational blindness, failing to distinguish between productive work and "idle time" caused by maintenance or material shortages.

The Compliance Minefield

Regulatory compliance is a multi-layered challenge. OSHA explicitly identifies worker fatigue as a hazard; accident rates are significantly higher on night shifts. A robust time and attendance system acts as a safety barrier, utilizing "fatigue management" rules to proactively block scheduling if an employee lacks mandatory rest periods. This moves the software from an administrative tool to a critical risk management asset.

TimeTrex – A Paradigm of Secure Workforce Management

TimeTrex has carved a unique niche for industries with high security requirements like manufacturing. It replaces fragmented spreadsheets with a unified digital ecosystem, automating the flow from the initial "punch" to the final paycheck to eliminate data re-entry errors.

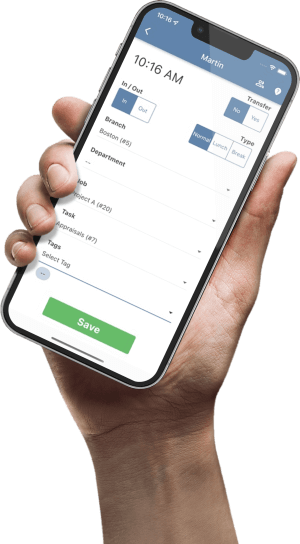

The Digital Workflow

Biometric Punch

Facial recognition or fingerprint scan eliminates buddy punching.

Geo & Job Validation

GPS fencing confirms location; Job Codes track specific tasks.

Auto-Processing

Rules engine applies overtime, rounding, and accruals instantly.

Manager Approval

Exceptions flagged for review. One-click batch approval.

Payroll Integration

Clean data exported directly to payroll providers.

Architectural Philosophy and Security

While competitors often force a cloud-only model, TimeTrex offers a critical differentiator: On-Site (On-Premise) Deployment. For high-stakes manufacturing (e.g., aerospace, defense), this allows the software to operate in an "air-gapped" environment, ensuring sensitive data never leaves the physical security perimeter.

The Biometric Revolution

Factory floors characterized by grease and dust wreak havoc on traditional fingerprint scanners. TimeTrex addresses this with a Touchless Facial Recognition System. The system converts facial scans into encrypted digital codes (hashes), ensuring hygiene and preventing identity theft, while decisively solving "buddy punching."

Granular Job Costing and Financial Integration

For a manufacturer, "Gross Pay" is an insufficient metric. To understand true profitability, they must know the Cost of Goods Sold (COGS), which requires breaking down labor costs by job, project, or production line.

Job Costing: Labor Intensity Map

Advanced analytics visualize labor costs per production line hour-by-hour. Darker areas indicate higher labor cost density.

TimeTrex’s Job Costing module allows employees to clock into specific "production runs." If a worker spends 4 hours on "welding" and 4 hours on "assembly," wages and overheads are allocated proportionally. This granular view helps manufacturers identify unprofitable activities and create accurate bids.

Comparative Market Analysis

To contextualize TimeTrex’s position, it is necessary to compare it against other industry heavyweights like ADP Workforce Now and Kronos (UKG). The market is bifurcated between generalist HCM suites and specialized workforce management tools.

While ADP is a "generalist" platform, it often lacks the flexibility for complex manufacturing rules and lacks an on-premise option. Kronos is powerful but often viewed as a legacy system requiring expensive proprietary hardware.

As shown in the chart, manual methods may seem low cost initially, but they score lowest on accuracy and compliance, creating hidden long-term costs.

System Maturity Comparison

| Feature Category | TimeTrex | ADP Workforce Now | Kronos (UKG) |

|---|---|---|---|

| Deployment | Hybrid (Cloud or On-Premise) | Cloud (SaaS) Only | Cloud / Legacy On-Prem |

| Data Sovereignty | High (Air-gap capable) | Low (Vendor held) | Medium |

| Biometrics | Facial Recognition (Tablet-based) | Partner Integrations | Proprietary Hardware |

| Job Costing | Granular (Task/Project level) | General (Department level) | Advanced |

The Economic Impact and ROI of Automation

Investing in a system like TimeTrex is a financial investment with a calculable Return on Investment (ROI). The elimination of payroll errors (estimated at 1-3% of total payroll) and the reduction of time theft via "buddy punching" provide immediate financial returns.

Average drop in unauthorized OT in first quarter.

Reduction in time spent calculating payroll.

Accuracy in data transfer to payroll.

Cumulative Savings Projection (Year 1)

Legal Nuances and Compliance Strategy

The regulatory environment for manufacturing is a patchwork of federal and state laws. A unified WFM system must apply geofenced logic. For example, TimeTrex can apply the Federal Default rules to employees in Texas, while simultaneously applying stricter daily overtime and meal break rules to employees in California, even within the same job code.

Furthermore, "Fair Workweek" laws penalize back-to-back shifts with insufficient rest. TimeTrex triggers alerts when a manager attempts to schedule a violation, creating an irrefutable audit trail.

Implementation Best Practices

Implementing TimeTrex requires a strategic approach. Before installation, manufacturers must document every unwritten rule of the shop floor to avoid "garbage in, garbage out." Hardware placement is critical; facial recognition kiosks should be at natural choke points like entry gates. Finally, engaging union representatives early regarding seniority and bidding rules is critical to adoption.

Ready to Optimize Your Manufacturing Workforce?

Stop relying on spreadsheets and legacy systems. Secure your data, automate your compliance, and gain real-time visibility into your labor costs with TimeTrex.

Explore Manufacturing SolutionsDisclaimer: The content provided on this webpage is for informational purposes only and is not intended to be a substitute for professional advice. While we strive to ensure the accuracy and timeliness of the information presented here, the details may change over time or vary in different jurisdictions. Therefore, we do not guarantee the completeness, reliability, or absolute accuracy of this information. The information on this page should not be used as a basis for making legal, financial, or any other key decisions. We strongly advise consulting with a qualified professional or expert in the relevant field for specific advice, guidance, or services. By using this webpage, you acknowledge that the information is offered “as is” and that we are not liable for any errors, omissions, or inaccuracies in the content, nor for any actions taken based on the information provided. We shall not be held liable for any direct, indirect, incidental, consequential, or punitive damages arising out of your access to, use of, or reliance on any content on this page.

About The Author

Roger Wood

With a Baccalaureate of Science and advanced studies in business, Roger has successfully managed businesses across five continents. His extensive global experience and strategic insights contribute significantly to the success of TimeTrex. His expertise and dedication ensure we deliver top-notch solutions to our clients around the world.

Time To Clock-In

Start your 30-day free trial!

Experience the Ultimate Workforce Solution and Revolutionize Your Business Today

- Eliminate Errors

- Simple & Easy To Use

- Real-time Reporting

Saving businesses time and money through better workforce management since 2003.

Copyright © 2025 TimeTrex. All Rights Reserved.